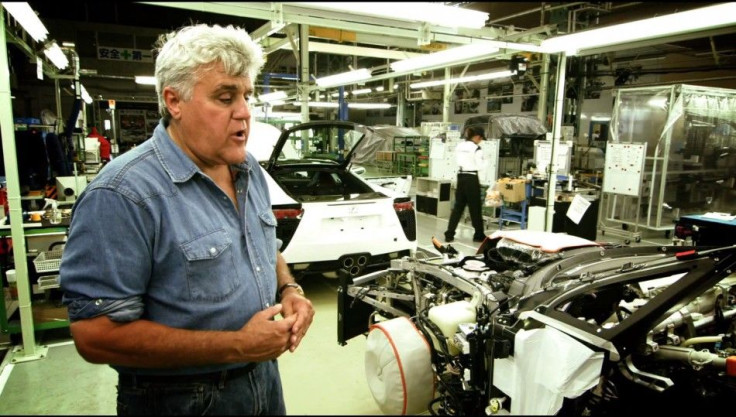

Taking a trip to Japan, American talk show host and bona fide car guy Jay Leno visits the Lexus LFA factory for a first hand look at how the Japanese supercar is made.

Starting with the raw elements, Toyota's textile loom heritage comes in handy as it demonstrates its intricate carbon-fiber loom machine, responsible for all the bespoke carbon components necessary to build the LFA. Carbon fiber is often praised as the across the industry but its qualities are arguably best shown in the LFA than anywhere else -- its basic tube architectures is stronger than steel yet weighs less than 20 kilograms and acts as the fundamental structure of the machine.

The total build time from bare components to a complete Lexus LFA sports car takes three days and nearly every piece is assembled by hand. After assembly is finished, the LFA must still remain in the factory for another ten days to undergo 7,000 quality inspections.

To car enthusiasts that criticize the Japanese for building souless machines, take a look at the amount of passion these highly trained technicians have for the Lexus halo supercar.

As an added bonus, Jay Leno's visit to the LFA factory ends with a trip to Fuji Speedway where he gets to sit behind the wheel of the world's one and only Lexus LFA Spyder.

Check out Jay Leno's awesome trip in the video below!